Latest AUTEL MaxiDAS DS808 Handheld Touch Screen Autel Diagnostic Tools Update Online

Go And Check Now! Here>>>>

Note:

1. No need to wait until Black Friday, get the lowest prices now

2. Free shipping from the US/UK/EU, fast, and no tax.Enjoy!

For tech support Pls Contact Erin:

WhatsApp: +86 18054815707

Email: Sales@EOBD2shop.com

Related Download Files

Product Description

Top 4 Reason To Buy the Autel MaxiDAS DS808

2.Convenient data management system for managing internal program applications and reviewing data

3.One-stop multitasking designed for ideal management of workshop operations to keep all data files, customer info, and vehicle records well organized

4.Autel Maxidas DS808 Automotive OBD2 Scanner Diagnostic Tool Key Coding & Multi-language System the Same Function As MS906(Upgraded Version of DS708).

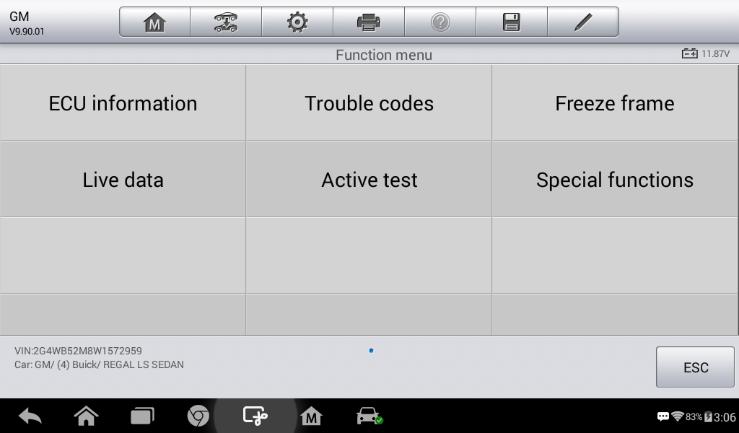

Note: There are two options available when accessing the Diagnosis section:

1. Auto Scan – starts auato scnning for all the available systems on the vehicle.

2. Control Units – displays a selection menu of all available control units of the test vehicle.

After a section is selected and the tablet establishes communication with the vehicle, the corresponding function menu or selection menu displays.

What is the difference between Autel MaxiDAS DS808 And Autel MaxiPro MP808 Series

Autel MaxiDAS DS808 compare with Autel MaxiPro MP808, MP808BT and MP808TS. Autel MaxiDAS DS808 has same hardware as Autel MaxiPro MP808 Series. Quad-core 1.6GHz, Android 4.4.4,1G + 64G Memory, 7″ LCD Display, 5000mAh Battery. Autel MaxiPRO MP808TS has more comprehensive TPMS functions, Autel MaxiDAS DS808 and Autle MaxiPro MP808 not support battery analysis.

Comparison Table:

| MaxiDAS DS808 | MaxiPRO MP808 | MaxiPRO MP808BT | MaxiPRO MP808TS | |

| Read Codes | √ | √ | √ | √ |

| Erase Codes | √ | √ | √ | √ |

| Live Data | √ | √ | √ | √ |

| ECU Information | √ | √ | √ | √ |

| Active Test | √ | √ | √ | √ |

| Service Functions | √ | √ | √ | √ |

| Complete OBD Diagnostics | √ | √ | √ | √ |

| Oil Service Reset | √ | √ | √ | √ |

| Parking Brake Pad Relearn After Replacement | √ | √ | √ | √ |

| Steering Angle Sensor Relearn | √ | √ | √ | √ |

| Battery Registration and Reset | √ | √ | √ | √ |

| Diesel Particulate Filter Regeneration | √ | √ | √ | √ |

| Tire Pressure Monitoring System | Basic | Basic | Basic | Complete |

| Immobilizer Function | Basic | Basic | Basic | Basic |

| Advanced TPMS Diagnostics for Complete TPMS Health Check | — | — | — | √ |

| Activate 98% of All Known TPMS Sensors | — | — | — | √ |

| Program AUTEL MX-Sensors | — | — | — | √ |

| Comprehensive OBD relearn coverage | — | — | — | √ |

| On-screen Relearn Procedure | — | — | — | √ |

| Battery Analysis | — | — | √ | √ |

| Videoscope | √ | √ | √ | √ |

| Processor | Quad-core 1.6GHz | Quad-core 1.6GHz | Quad-core 1.6GHz | Quad-core 1.6GHz |

| OS | Android 4.4.4 | Android 4.4.4 | Android 4.4.4 | Android 4.4.4 |

| Memory | 1G + 64G | 1G + 64G | 1G + 64G | 1G + 64G |

| Display | 7″ LCD | 7″ LCD | 7″LCD | 7″LCD |

| Battery | 5000mAh | 5000mAh | 5000mAh | 5000mAh |

| Internet Updatable | WiFi | WiFi | WiFi | WiFi |

| Multilingual Support | √ | √ | √ | √ |

| Historical Test Records | √ | √ | √ | √ |

| Save and Playback Data | √ | √ | √ | √ |

| Print Data via Windows PC | √ | √ | √ | √ |

| Vehicle communication method | Wired | Wired | Wireless (bluetooth) | Wireless (bluetooth) |

Complete capabilities for codes, live data, active test, ECU information, adaptation, matching, etc.

Smart AutoVIN technology for identifying vehicles easily

Automatic system and software updates with real-time push message notifications via Wi-Fi

Instant remote control tech support anytime, anywhere

Cloud-based MaxiFix online community provides a vast database of diagnostic and repair tips and proven filed fixes

Interactive Data Logging sessions enable direct contact with Autel Technical Support for first-hand troubleshooting of diagnostic bugs and error

How to update Autel DS808 software:

2. Tap the Update application button from the MaxiDAS Job Menu;

or tap the update notification message when received one;

or tap the Update icon on Vehicle Menu in Diagnostics application.

The Update application screen displays.

3. Check all available updates:

If you decide to update all the items, tap the Update All button.

If you only want to update one or some of the item(s), tap the Update button on the right column of the specific item(s).

4. Tap the Pause button to suspend the updating process. When you tap Continue to renew the update, the updating process will resume

from the break point.

5. When the updating process is completed, the firmware will be installed automatically. The previous version will be replaced.

MaxiDAS DS808 Specifications:

Processor:Cortex-A9 processor (1.5 GHz)

Memory :32GB

Display:7-inch LCD capacitive touchscreen with 1024x600 resolution

Connectivity:• Mini USB 2.0 • USB 2.0 • Wi-Fi • Micro SD card (supports up to 32GB)

Sensors:Ambient light sensor for brightness auto changing

Audio Input/Output:• Input: N/A • Output: buzzer

Power and Battery:• 3.7 V/3200 mAh lithium-polymer battery • Charges via 5 VDC power supply

Tested Battery Life:Around 4.5 hours of continuous use

Battery Charging Input:5 V/1.5 A

Power Consumption:500 mA (LCD on with default brightness, Wi-Fi on) @3.7 V

Operating Temp:-10 to 60°C(14 to 140°F)

Storage Temp:-20 to 70°C (-4 to 158°F)

Operating Humidity:5% - 95% non-condensing

Dimensions (W x H x D):237.8 mm (9.4”) x 148.6 mm (5.9”) x 35.5 mm (1.4”)

Net Weight:788 g (2.42 lb.)

1pc x Power Adapter

1pc x USB External Power AdapterUser

1pc x ManualQuick reference guide

1pc x Main cableCarry case

1pc x Mini USB Cable

Shipment Option and Delivery Time In EOBD2shop

1. Shipment from Shenzhen/ Hongkong warehouse

1)DHL Shipping and Other Express Service:

- Take About 5-7 working days

- DHL will be the default delivery method

- To help you clearance we will help declare a lower price on the invoice to help clearance.

- If address is remote area, you need pay remote freight 45 USD or we will ship by Normal Post or Yanwen/EMS/Aramex Express.

- For some eu countries, there might be customs duty problem, if you have any special rquest on this, you can email to inform us your suggestions.

- Take About 7-10 working days, No Tax Problem

- Usually No Tax for European Countries or Remote Area. The tax was pre-paid, when package reached, there's no tax no extra fee for customers.

- Due to high custom tax in European Countries, Like Canada, Germany, Greece, Romania, Sweden, France,etc, we will use Yanwen express as first option, if you will need faster DHL shipment, please contact us, thank you.

- Take About 10-16 working days, Sometimes will be 20 days.

- Registered Airmail Includes Netherlands Post, USPS Post, Singapore Post, Hongkong Post, etc

- Order amount less than 150USD, and package weight less than 2KG will be sent by Registered airmail.

- But if you feel it is really slow, and want us to send by DHL, you can choose "Premium Delivery" and pay for the extra shipping for express service. finally we will send it by DHL.

- Item title marked "Ship from US"

- Take About 3-5 working days, Free TAX, faster shipping with cheaper price.

- Note: If US/UK Stock sold out, your order will be shipped from China via DHL or YANWEN (No Tax) by default.

- We have stocked up hot sale items in US, UK, Amazon US, and EU Warehouse, which is more convenient for you.

- EU Warehouse was located in Germany/Czech and it only can ship to EU country:

Germany, France, Spain, Netherlands, Finland, Sweden, Austria, Belgium, Bulgaria, Croatia,

Czech Republic, Denmark, Estonia, Greece, Hungary, Ireland, Latvia, Lithuania,Luxembourg,

Malta, Poland, Portugal, Republic of Cyprus, Romania, Slovakia, Slovenia,5-7 DaysRoyal Mail/ DHL

We can offer you lifetime customer service and tech support. If you have any problems, please Provide error image or video to show the problem, and kindly describe it in detail, technician will try their best to help you solve the problem. If there are no solution, you can return it for refund or get a new one for replacement.

For any question, please contact us at:

- Whatsapp: +8618054815707

- Email: sales@EOBD2shop.com

- Hot line: +8618054815707

- Skype: careucar

- Accepting bulk purchases, We can Offer you wholesale price.

- EOBD2shop is a OBDII tool online supplier providing best-quality ECU chip uning tools, car diagnostic tools, OBDII Code scanners, car key programmers, heavy duty scanners, locksmith tools etc.

- Besides, we are the agent for many original brand such as Autel, Xhorse, OBDstar, VXdiag, XTOOL,Launch,CGDI, Yanhua ect.

Tech support

1.Customer feedback for Autel MaxiDAS DS808 Full Kit Coding Scanner

Paid one Autel Maxidas DS808 scanner and service reset tool oneOBDShop and was asked to provide an objective review on its operation and capabilities. I was interested to see how things had developed for Autel, as my previous experience of Autel diagnostic equipment was the first generation, Autel Maxidas DS708.

- First impression to the full package

When Maxidas DS808 arrived at me, the carry case looked something differently as the Autel DS808. Inside the case the host hardware was a compact, smart, rugged, android tablet. This was partnered by many good quality diagnostic adapters including those non-standard 16pin connectors, as well as a thick user manual on how to operate this machine.

- Autel Maxidas DS808 tablet

The Autel Maxidas DS808 tablet was light and compact and was very comfortable in hand. For such a compact package, the Power Sources is optional incl.: Internal Battery Pack, vehicle power, external power supply by connecting the packed power adapter. For the battery life it has a large capacity 3.7 V/3200 mAh lithium-polymer battery. Besides its new processor (Cortex-A9 processor (1.5 GHz), 7.0” LCD Capacitive Touchscreen and the Ambient Light Sensor which can detect ambient brightness when it is inside the workshop, thanks to the screen finish and a good quality display.

Autel MaxiDAS DS808 Full Kit User Manual

- Feeling on general use – quick and smart to operate and update

The software look and feel are both very good in terms of layout and size and the touch screen operation worked flawlessly in conjunction with its large, clear icons. Ds808 was quick to get going from the initial power up to operate. The response in moving through the menus and executing tasks was immediate.

Downloading and running updates speed (which depends on the internet connection speed) was reasonable. The ‘services/update’ section of the software on the Autel DS808 notifies the user of pending updates, and it’s a ‘click and go’ procedure to set the updates running. And During general use I found that the Wifi communication connected stably when I used it.

- Autel DS808 performance:

The Autel Maxidas DS808 has wide and comprehensive system coverage, covers all of the prevailing makes and models. A detailed report of software coverage was beyond the scope of my brief. However, I did use the Autel Maxidas DS808 for a typical range of general workshop tasks (ECU information, trouble codes, freeze frame, live data, active test and special functions) on a typical range of workshop makes and models.

Also the “auto detect VIN” and “manually input VIN” are user-friendly design.

- Graphing a live data stream:

One of the features I believe that a diagnostic scan tool should have is graphing a live data stream. The reason that this is so important is to enable the vehicle technician to examine the relationships between the various sensors, actuators and calculated values. This is critical for intermittent fault finding and for vehicle problems which don’t set diagnostic trouble codes. In this respect the Autel Maxidas DS808 did a good job. The live data is selected from an array of available parameters and then graphed. The graphed data can be shown as separate graphs or combined in a job graph. The scales are auto ranging and they can be reset to align them to the current operating conditions.

- Many special functions

Another nice feature is its special functions, especially when it compares with maxidas ds708. These functions perform various component adaptations, allowing you to recalibrate or configure certain components after making repairs or replacement.

The main menu displays the supported special functions for the test vehicle. Follow the on-screen instructions to complete the desired function. When the operation is done, an execution status message such as Completed, Finished or Successful, displays. Tap the ESC button to exit the function.

The most commonly performed service functions include: Oil Reset Service, TPMS Programming Service, EPB Service, ABS/SRS Services, SAS Calibration Service, DPF Regeneration Service

By following the on-screen instructions to select appropriate execution options, enter correct values or data, and perform necessary actions, the system will guide my through the complete performance for various service operations.

Using ds708 many years, so I quickly find there are several applications are newly developed, they are AutoVIN Technology, MaxiFix Cloud-based information system, Shop manager. Valuing the user experience is the Company soul, I think Autel Company do a good job. I try these new applications one-by-one, and prove what they claim in the following table.

Using ds708 many years, so I quickly find there are several applications are newly developed, they are AutoVIN Technology, MaxiFix Cloud-based information system, Shop manager. Valuing the user experience is the Company soul, I think Autel Company do a good job. I try these new applications one-by-one, and prove what they claim in the following table.

- Data logging reports: submit via wifi and print

Autel Maxidas DS808 is allowed to submit Data Logging Reports in diagnostics.The reports are saved to the internal memory (which is a not insignificant 32 GB, depending on the hardware specification). As the tablet is equipped with WIFI, these can be emailed to the office or directly to the customer.

The Data Manager application is used to store, print, and review the saved files. Most operations are controlled through the toolbar.

The reports are able to be saved in PDF format

In the toolbar buttons, you could see the “Print”, click it and go. Printing the reports directly is a little more challenging. In my case, I had to install a separate PDF viewer, and to realize the wireless data printing function, I need to install the printer driver program by following the instruction. This made getting the reports off the device a little long winded. My opinion is that it would be more convenient if the print button could be configured to call other installed printer drivers.

- TeamViewer Quick Support program:

The “Remote Desk” app is remarkable, it launches the TeamViewer Quick Support program, it is a simple, fast and secure remote control screen. I could use it to receive ad-hoc remote support from Autel’s support center, colleagues, or friends, by allowing them to control my MaxiDAS tablet on their PC. Therefore I need not phone call any more. TeamViewer ID would be the phone number. Make sure the Display Tablet is connected to the Internet before launching the Remote Desk application.

Conclusion:

I think highly of Autel Maxidas DS808, I highly recommend it to the small repair shop. It is rugged, running fast, easy to use, light and add many special functions comparing autel ds708.

2.This a how-to guide of 2017 Autel DS808 registration.

– Necessary to perform Autel DS808 registration?

– Definitely yes! To get access to the Support platform and obtain update and other services from Autel, you are required to register the Autel scanner DS808 for the first time you use it.

– What you need for the maxidas ds808 registration?

1- autel scanner ds808

2- account id

3- serial number & password

– How to register autel maxidas ds808?

Go to the website: http://pro.autel.com.

On the Sign In page, input your account ID and other information to

log in, if you already have an account.

If you are a new member to Autel and do not have an account yet,

click the Create Autel ID button on the left side.

Enter the required information in the input fields, read through

Autel’s Terms and Conditions and tick on Agree, and then click

Create Autel ID at the bottom to continue.

The online system will automatically send a confirmation email to

the registered email address. Validate your account by clicking the

link provided through the mail. A product registration screen opens.

Find out the scanner’s serial number and password from the About

section of the Settings application on the Display Tablet.

Select the product model of your DS808 scanner, enter the product serial

number and password on the Product Registration screen, and click on

Submit to complete the registration.

3. How to use Autel MaxiDAS DS808 diagnostic scanner?

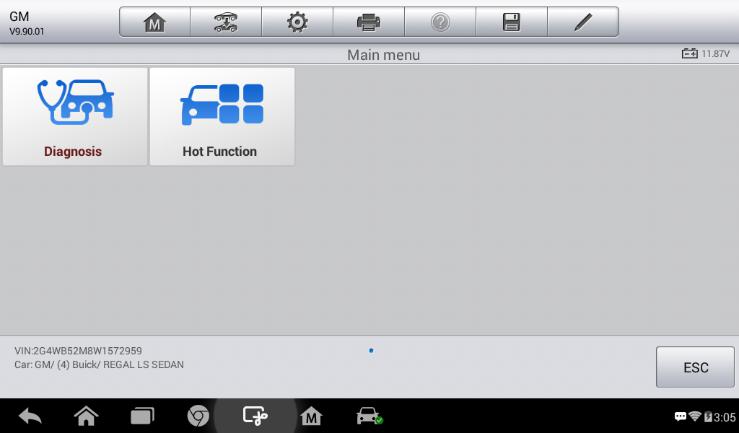

The Autel DS808 diagnostics application allows you to establish a data link to the electronic control system of the test vehicle for vehicle diagnosis. You can operate functional tests, retrieve vehicle diagnostic information such as trouble codes, freeze frame data and live data for various vehicle control systems, such as engine, transmission, ABS, and more. The Vehicle Diagnostics screen has 2 main options:

- Diagnosis – a comprehensive section which includes all available functions: reading, clearing, saving and printing diagnostic information, as well as performing active tests and special functions.

- Hot Function – a separate section designed to perform vehicle scheduled service and maintenance, such as to reset the service lights and perform calibration for various systems.

After a section is selected and the tablet establishes communication with the vehicle, the corresponding function menu or selection menu displays.

Diagnosis

There are two options available when accessing the Diagnosis section:

- Auto Scan – starts auto scanning for all the available systems on the vehicle.

- Control Units – displays a selection menu of all available control units of the test vehicle.

After a section is selected and the tablet establishes communication with the vehicle, the corresponding function menu or selection menu displays.

Auto Scan

The Auto Scan function performs a comprehensive scanning over all the ECUs in the vehicle’s systems in order to locate and retrieve DTCs. The sample operation screen of Auto Scan displays as below:

Control Units

This option allows you to manually locate a required control system for testing through a series of choices. Please follow the menu driven procedures and make proper selection each time. The program will guide you to the diagnostic function menu after a few choices you’ve made.

The Function Menu options vary slightly for different vehicles. The function menu may include:

ECU Information – provides the retrieved ECU information in detail. Tap to open an information screen.

Trouble Codes – includes Read codes and Erase codes functions. Displays detailed information of DTC records retrieved from the test vehicle’s ECU and erases DTC records and other data from the test vehicle’s ECU.

Freeze Frame – displays the freeze frame data of the DCTs.

Live Data – retrieves and displays live data and parameters from the test vehicle’s ECU.

Active Test – provides specific subsystem and component tests. This selection may appear as Actuators, Actuator Test, or Function Tests, etc., and the tests options vary depending on the manufacturer and model.

NOTE

With the diagnostic toolbar on top of the screen throughout the whole diagnostic procedures, you are allowed to make various controls of the diagnostic information at any time, such as printing and saving the displayed data, getting help information, or performing data logging, etc.

How to use Autel MaxiDAS DS808 to perform a diagnostic function:

- Establish communication with the test vehicle.

- Identify the test vehicle by selecting from the menu options.

- Select the Diagnosis section.

- Locate the required system for testing by Auto Scan or through menu driven selections in Control Units.

- Select the desired diagnostic function from the Function Menu.

ECU Information

This function retrieves and displays the specific information for the tested control unit, including unit type, version numbers and other specifications.

The sample ECU Information screen displays as below:

Read Codes

This function retrieves and displays the DTCs from the vehicle’s control system. The Read Codes screen varies for each vehicle being tested. On some vehicles, freeze frame data can also be retrieved for viewing. The sample Read Codes screen displays as below:

Erase Codes

After reading the retrieved codes from the vehicle and certain repairs have been carried out, you can erase the codes from the vehicle using this function.

Before performing this function, make sure the vehicle’s ignition key is in the ON (RUN) position with the engine off.

- Tap Erase Codes from the Function Menu.

- A warning message displays to inform you of data loss when this function is applied.

- a) Tap Yes to continue. A confirming screen displays when the operation is successfully done.

- b) Tap No to exit.

- Tap ESC on the confirming screen to exit Erase Codes.

- Perform the Read Codes function again to check if the code erasing is successful.

Live Data

When this function is selected, the screen displays the data list for the selected module. The items available for any control module vary from one vehicle to another. The parameters display in the order that they are transmitted by the ECM, so expect variation between vehicles.

Gesture scrolling allows you to quickly move through the data list. Simply swipe the screen up or down to locate the data you want. The figure below shows a typical Live Data screen:

Display Mode

There are 4 types of display modes available for data viewing, allowing you to view various types of parameters in the most suitable way.

Tapping the drop-down button on the right side of the parameter name opens a submenu. There are 4 buttons to configure the data display mode, and one Help button on the right that you can tap for additional information.

Each parameter item displays the selected mode independently.

1) Analog Gauge Mode – displays the parameters in form of an analog meter graph.

2) Text Mode – this is the default mode which displays the parameters in texts and shows in list format.

3) Waveform Graph Mode – displays the parameters in waveform graphs. When this mode is applied, three control buttons will appear on the right side of the parameter item, allowing you to manipulate the display status.

4) Digital Gauge Mode – displays the parameters in form of a digital gauge graph.

Full Screen Display – this option is only available in the waveform graph mode and mostly used in Graph Merge status for data comparison.

There are three control buttons available on the top right side of the screen under this mode.

- Select 1 to 3 parameter items to display in Waveform Graph mode.

- Tap the Zoom-in Button on the right to display the data graph in full screen.

- Select a parameter item on the left column.

- Select a desired sample color from the middle column.

- Select a desired sample line thickness from the right column.

- Repeat step 3-5 to edit the waveform for each parameter item.

- Tap Done to save the setting and exit, or tap Cancel to exit without saving.

Setting Mode in Live Data

Active Test

The Active Test function is used to access vehicle-specific subsystem and component tests. Available tests vary depending on the manufacturer, year, and model, and only the available tests display in the menu.

During an active test, the tester outputs commands to the ECU in order to drive the actuators. This test determines the integrity of the system or parts by reading the engine ECU data, or by monitoring the operation of the actuators, such as switching a solenoid, relay, or switch between two operating states.

Selecting Active Test opens a menu of test options that varies by make and model. Selecting a menu option activates the test. Follow on-screen instructions while performing tests. The content and pattern of the on-screen information vary according to the type of test being performed. Some toggle and variable control tests display Active Test Controls at the top of the screen with data stream information below, or vice versa.

The functional buttons at the lower right corner of the Active Test screen manipulate the test signals. The operational instructions are displayed on the main section of the test screen. Simply follow the on-screen instructions and make appropriate selections to complete the tests. Each time when an operation is successfully executed, message such as “Command Finished”, “Activation Successful”, or something similar displays.

Tap the ESC functional button to exit the test when finished.

Special Functions

These functions perform various component adaptations, allowing you to recalibrate or configure certain components after making repairs or replacement.

The main menu displays the supported special functions for the test vehicle.

Follow the on-screen instructions to complete the desired function. When the operation is done, an execution status message such as Completed, Finished or Successful, displays. Tap the ESC button to exit the function.

Hot Functions

The Service section is specially designed to provide you with quick access to the vehicle systems for various scheduled service and maintenance performances. The typical service operation screen is a series of menu driven executive commands. By following the on-screen instructions to select appropriate execution options, enter correct values or data, and perform necessary actions, the system will guide you through the complete performance for various service operations.

The most commonly performed service functions include:

Oil Reset Service

TPMS Programming Service

EPB Service

ABS/SRS Services

SAS Calibration Service

DPF Regeneration Service

Oil Reset Service

This function allows you to perform reset for the Engine Oil Life system, which calculates an optimal oil life change interval depending on the vehicle driving conditions and climate. The Oil Life Reminder must be reset every time the oil is changed, so the system can calculate when the next oil change is required.

Tire Pressure Monitor System (TPMS) Service

This function allows you to quickly look up the tire sensor IDs from the vehicle’s ECU, as well as to perform TPMS programming and reset procedures after tire sensors are replaced.

Electric Parking Brake (EPB) Service

This function has a multitude of usages to maintain the electronic braking system safely and effectively. The applications include deactivating and activating the brake control system, assisting with brake fluid control, opening and closing brake pads, and setting brakes after disc or pad replacement, etc.

ABS/SRS Services

This function allows you to perform various bi-directional tests to check the operating conditions of both the Anti-lock Braking System and the Supplemental Restraint System, such as Automated Bleeding, Pump Motor Test, and checking Module information, etc.

Steering Angle Sensor (SAS) Service

This service function allows you to perform calibration for the Steering Angle Sensor, which permanently stores the current steering wheel position as the straight-ahead position in the steering angle sensor EEPROM. On successful completion of the calibration, the steering angle sensor fault memory is automatically cleared.

DPF Regeneration Service

The Diesel Particulate Filter service function performs the regeneration procedure which is the DPF cleaning operation to clear the blockage through continuous burning of the particulate matter captured in the DPF filter. If the DPF light on the vehicle comes on and you successfully complete a DPF regeneration cycle, you will notice that the DPF light will automatically turn off.

![Original AUTEL MaxiSys MS908 MaxiSys Diagnostic System Update Online [ Buy SP351 Instead ]](/upload/pro-sm/14111220531777039.jpg)

![100% Original AUTEL MaxiSYS Pro MS908P Diagnostic System Support Key Coding come with J2534 MaxiFlash Elite [Buy SP331 Instead]](/upload/pro-sm/170629002911176061.jpg)